When turf starts shrinking, wilting, or melting in oddly specific spots, most homeowners assume the turf itself was poor quality. Turf installers often hear the same question: “Would this still happen if I bought better turf?”

The short answer:

Turf type can help, but reflective window glare can still melt almost any turf, including nylon.

Low-E windows and concave glass can create hot spots well above 200°F, hot enough to shrink polyethylene (PE), curl polypropylene (PP), and even damage nylon, which has a much higher melting point.

This guide explains how turf materials behave under window glare, when upgrading turf actually helps, and why prevention always beats replacement.

Nylon vs Polyethylene: Does Turf Type Really Matter?

Artificial turf is typically made from one of three plastics:

-

Polyethylene (PE) – Most common, softest underfoot

-

Polypropylene (PP) – Budget turf, lowest heat resistance

-

Nylon – Strongest and highest melting point

Here’s how each responds to window glare:

Polyethylene (PE): Most popular, but lowest heat tolerance

-

Begins to shrink and wilt around 175°F–200°F

-

Easily damaged by concentrated reflections

-

Responsible for most “melted divots,” “shiny lines,” and “crop-circle rings” you see in yards

PE is durable for normal weather, but no match for magnifying-glass hot spots from Low-E windows.

Polypropylene (PP): Lowest performance under heat

-

Softens even faster than PE

-

Used in lower quality turf products

-

Extremely vulnerable to glare from windows

PP turf almost always loses the battle against window reflection.

Nylon: Higher melting point, but still vulnerable under intense hot spots

-

Heat tolerance up to ~400°F, depending on the formulation

-

Holds shape much longer

-

Resists everyday heat and light

-

Still scorches under magnified, parabolic hot spots

Many homeowners are surprised that even nylon can show:

-

Matted texture

-

Brown “sunburn” patches

-

Melted tips

-

Warped infill

Because the issue isn’t the turf, it’s the temperature. A focused beam from a Low-E window can surpass 200°F–250°F, even in winter.

Why Hot Spots Still Win: The Window Reflection Problem

Low-E windows are designed to reduce energy loss by reflecting heat, but that same coating can create a mirror-like glare on sunny days.

Under the right angles, that glare becomes a:

-

concentrated hot spot

-

parabolic reflection

-

magnifying-glass effect

This beam moves predictably across the yard as the sun shifts, melting turf in straight lines, stripes, wavy patterns, or circular rings.

Even the best turf material cannot out-perform physics. If the window reflection consistently hits the same area, melting or shrinking will happen again, no matter what turf you install.

Will Upgrading Your Turf Help? When It Will, and Won’t

Upgrading helps when:

-

You need more physical durability

-

You want better resilience under normal sun heat

-

Your window glare is mild but consistent

-

You have light discoloration, not melting

Nylon turf can delay damage, but not prevent it entirely.

Upgrading won’t help when:

-

Melt patterns follow a diagonal path across the yard

-

You see crop-circle rings or deep divots

-

Turf melts only at specific times of day (e.g., 1–3 p.m.)

-

The turf is near a neighbor’s Low-E window

-

The window glass is slightly concave, amplifying heat

In these cases, the window, not the turf, is the problem.

Replacing turf without stopping the reflection guarantees one thing: You’ll be replacing it again.

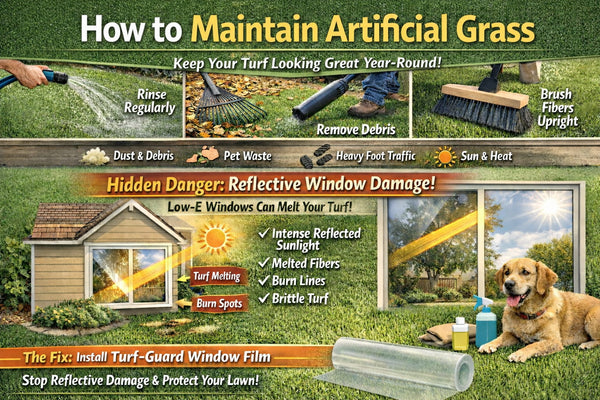

Prevention Beats Replacement: How to Stop Turf Melt Completely

The only long-term solution is blocking or diffusing the reflection at the window.

Proven fixes include:

1. Exterior Turf-Guard Window Film

- Breaks up the concentrated beam so the turf never overheats.

- Does NOT noticeably change window appearance.

- HOA-friendly.

2. Solar Screens

- Breaks up the concentrated sun beam.

- HOA-friendly in many neighborhoods.

- Last 10+ years

3. Shade Solutions (awnings, shade sails, shutters)

- Helps when window film and solar screens aren't an option.

4. Strategic Landscaping (trees, shrubs, fences)

- Useful for blocking glare if other solutions are not an option.

Upgrading your turf is optional.Stopping the reflection is a must.

How to Tell If Your Turf Is Melting from Window Glare

You’re likely dealing with window reflection if you see:

-

Melted divots or shiny lines

-

Matted or shrunken blades

-

Diagonal melt paths

-

Repeated damage in the same area

-

Melting only during certain hours

To confirm:

-

Stand in the damaged spot during the hour you suspect melting.

-

Turn toward your home or a neighbor’s home.

-

Look for a bright flash or shimmer of reflected sunlight.

-

Take a photo or video for documentation.

This is the diagnostic method used by inspectors, HOAs, and turf installers nationwide.

FAQs: Nylon Turf vs Poly Turf and Window Glare

Does nylon turf resist melting better than polyethylene?

Yes, nylon has a higher melting point, but intense window glare can still scorch or distort it. Nylon delays heat damage but cannot prevent it when temperatures exceed 200–250°F.

Will switching turf types stop melted spots from coming back?

Not if the hot spot is caused by window reflection. The damage will return until the reflection is diffused or blocked.

What turf type melts the fastest?

Polypropylene (PP) melts fastest, followed by polyethylene (PE). Nylon lasts longer but is not melt-proof.

What’s the best permanent fix for melted turf?

Installing exterior Turf-Guard Window Film or Solar screens.

Can a neighbor’s window melt my turf?

Yes. Second-story windows and concave Low-E glass can cause hot spots up to 30 feet away.